Outcome Example of Bio-oriented Technology Research Advancement Institution

Issued on November 2, 2020

A potential of algae as a savior for fossil fuels

Do you know that minute algae inhabiting waters, such as seas and ponds, generate oil, of which components are similar to those of petroleum? The research and development where a mass of "Botryococcus," one algae species, is cultured and used as fuels for airplanes and vehicles and raw materials for cosmetics, supplements, and plastic products. The cosmetics containing oil extracted from algae have already developed and placed on the market. In future, algae have the potential to solve the problem of depletion of fossil fuels as a savior.

Botryococcus can be harvested year-round in 4 to 5 days

Algae can perform photosynthesis using sunlight and accumulating produced oil. A study mass-culturing the algae and aiming at converting the cultured algae into the raw material for an alternative fuel to petroleum is conducted by specially appointed professor Makoto Watanabe at the University of Tsukuba (Director of the Algae Biomass and Energy System R&D Center).

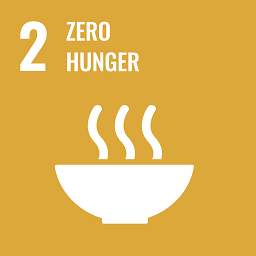

These species of algae generally produce oil in their cells and temporarily accumulate the produced oil within the cells. The species of Botryococcus discovered by professor Watanabe in Okinawa has a characteristic that it accumulates 90% of produced oil outside the cells (Image 1). Botryococcus is minute in size, about 1/100 mm.

|

The process to produce biofuels from algae, such as Botryococcus, involves four steps. "Culturing," "concentrating/harvesting," "extracting oil," and "converting into fuels."

Professor Watanabe succeeded in extracting hydrocarbon from living Botryococcus without destroying cells.

Botryococcus cells may survive to perform photosynthesis and accumulate a similar amount of carbohydrates even after extracting hydrocarbon every four days. Accordingly, hydrocarbon oil may be continuously extracted every 4 to 5 days.

Assuming that a culture pool with 20 cm in water depth is installed in a 1 ha fallow soil to culture Botryococcus without destroying cells and maintained for a year, 90 tons or more hydrocarbon oil might be extracted per year. Botryococcus proliferates during the warm season only; however, about 45 tons of yield, which is the highest standard algal oil production, can be expected.

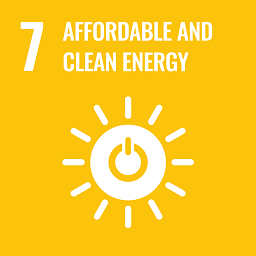

Moreover, an innovative technique called "hydrothermal liquefaction," by which a wide variety of algal species inhabiting the natural world are directly converted into crude oil, was developed (Image 2). With the "hydrothermal liquefaction" technique, a mixture of various algae is cultured in unprocessed sewage. The concentrated mixture is processed under high-temperature, and high-pressure conditions convert into crude oil.

This technique provides four characteristics described below. 1) Algae may be cultured using sewage the whole year. 2) Both the cost of fertilizers for algae and the cost of sewage disposal may be saved simultaneously. 3) With no oil extraction, algae may be directly converted into crude oil. 4) The culture pool with 1.5 m or more in water depth may be installed. Thus, 1,000 tons of annual crude oil production can be expected in a 1 ha area at almost the same cost as petroleum.

|

(Images 1, 2: by professor Watanabe)

Professor Watanabe says, "It is the most important issue to be solved whether a mass of algae may be efficiently cultured at a low cost. Effectively using processed sewage, it will be no longer a dream to produce oil at the cost of 50-yen level per liter shortly."

Advent of algal extract combination hand cream

Against this background, DENSO, a leading auto parts maker (Kariya, Aichi), developed algal extract combination hand cream "moina" (Image 3 supplied by DENSO) using hydrocarbon oil produced by Botryococcus as a cosmetic ingredient, which is a fruit of the joint research with University of Tsukuba and put it on the market in 2014. The ingredients of hydrocarbon extracted from Botryococcus is similar to those of shark liver oil. Focusing on this advantage, they challenged the culture of Botryococcus in their facility, and their efforts bore fruit. About 300 g of oil can be produced from 1 kg of Botryococcus. On a mission to develop a hand cream using the algal oil, the project team comprising women members elaborated the hand cream container based on women's suggestions, resulting in the successful production of the highly rated hand cream. This hand cream product is available via the Internet.

Algae and biofuels

| About 40,000 species of algae have been known. However, far more species may inhabit the natural world. Algae include large-sized species such as Wakame seaweed and tangle seaweed while most algae are minute organisms. Biofuels may be produced from vegetables, including corn, soybeans, and rapeseed. However, in terms of yield per ha, algal material for oil has an advantage that its yield is equivalent to several tens to hundreds of times that with vegetables. Algae have considerable advantages because they are almost not consumed by humans as edible food and that they may be cultivated in large amounts effectively using fallow soils. |

|

Project name

Research Program on Development of Innovative Technology (The former Agricultural / Food Industry Scientific Research Promotion program (Advancement / assimilation stage)

Project period

FY 2013 to 2014

Title

Establishment of a technique of effectively utilizing algal biomass on a large scale taking advantage of fallow soils

Project research institutes

University of Tsukuba (Tsukuba, Ibaraki), DENSO (Kariya, Aichi), and other institutes