(This is an English translation of the original Japanese article.

The publication date refers to that of the Japanese version,

which differs from the upload date of the English version.)

The Spotted Halibut (Photo 1) has been gaining attention as a new species for aquaculture* due to its rarity and high market value. However, the high production cost of its juvenile fish (artificial seedlings) used for farming and releasing has hindered the commercialization of spotted halibut aquaculture. To address this challenge, a research group consisting of eight organizations, led by the National Association for the Promotion of Productive Seas, worked to optimize the process of producing juvenile spotted halibuts, through the application of a set of technologies including the labor-saving low-cost raising method and the green LED light irradiation technology. This research project led to the establishment of a system for mass-producing healthy juvenile fish in a stable manner at a low cost, and to the development of a manual for introducing this system. As a result of this research outcome, it has become possible to release about 500,000 juvenile spotted halibuts in the Pacific coastal area of the Tohoku region, inviting expectation for an increase in catch of the fish species. Furthermore, as the technology the research group has developed for closed-cycle breeding, as well as its growth-promoting rearing technology using green LED light irradiation, can be applied to the land-based aquaculture, the research outcome has also raised the potential for commercialization of this type of aquaculture.

Photo 1: Spotted Halibut - A large species with black markings on its dorsal fin and other areas, which are likened to star-shaped patterns, hence the name. Due to its scarcity and high market value, it is attracting attention as a target species for aquaculture.

(provided by the Fisheries Research and Education Organization)

Establishing juvenile fish production system

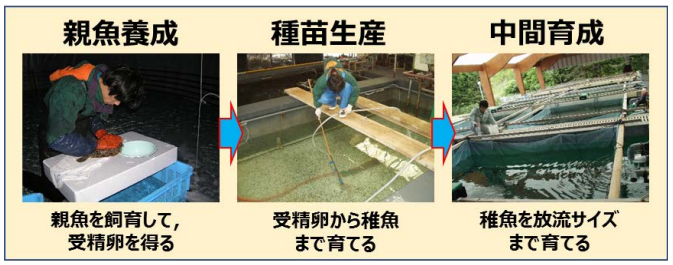

The production process of juvenile fish (artificial seedlings, Figure 1) can be divided into three stages: 'broodstock management' where parent fish are raised to obtain fertilized eggs,'seedling production' where fertilized eggs are raised to produce fingerlings, and 'intermediate rearing' where fingerlings are raised to juvenile fish, whose size is suitable for release or the start of farming. In the case of difficult-to-raise spotted halibut, there were many problems such as death and poor growth in each stage, making it impossible to raise a large number of healthy juvenile fish. As a result, the price of a juvenile fish (8cm) was very high at 180 yen, and cost reduction was a challenge for the commercialization of spotted halibut aquaculture.

Figure 1: Production process of juvenile fish: (from left to right) broodstock management, seedling production and intermediate rearing

(provided by the Japan Fisheries Research and Education Agency)

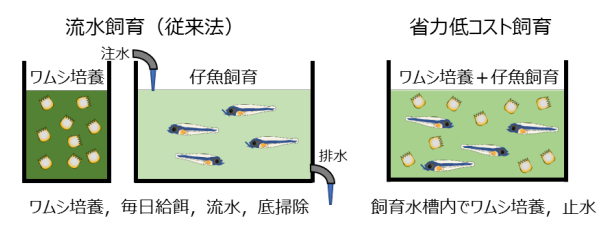

The research group has clarified that in the broodstock management, even with a simple closed-circulation system that is cheaper to operate and maintain than conventional running water tanks, high-quality fertilized eggs can be stably obtained. This is the first time for spotted halibut that stable egg collection has become possible through closed circulation breeding. In the seedling production, the group has introduced a low-cost and labor-saving method (Figure 2) where newly hatched fry and rotifers (a kind of plankton for feed) are cultivated together in one tank, thereby reducing the labor by 50%. In the intermediate rearing, it has been clarified that irradiating green LED light during the process has a more significant growth-promoting effect than natural light. From these research results, the research group established a set of technologies to stably produce a large number of healthy juvenile fish (survival rate of 80% or more) on a mass production scale (approx. 500,000 fish). The price of a release-sized juvenile fish (8cm) has been reduced from 180 yen to 40 yen, achieving a significant cost reduction.

Figure 2: Schematic diagram of seedling production by conventional method (left) and labor-saving and low-cost raising (right)

(provided by the Japan Fisheries Research and Education Agency)

Applying developed technology to land-based aquaculture, reducing raising time from two years to one

In this research project, significant growth promotion effects have been confirmed in the intermediate rearing by using green light.

This technology is now being applied to land-based aquaculture of spotted halibut and other species. In a demonstration test using irradiation of green LED light, the growing period to reach market size (weighing approx. 700g and 40cm long) was shortened to one year, whereas it took two years under natural light. The green LED lamp used for this test was developed by the research group in accordance with the light perception of flatfish species (Photo 2).

Photo 2: Indoor aquaculture area with green LED light irradiation

(provided by the Japan Fisheries Research and Education Agency)

Professor Akiyoshi Takahashi of Kitasato University, a member of the research group and an expert in this research field, explains why green light is effective rather than other colors: "Green light reaches well to the habitat of flatfishes at the bottom of the sea, which may have a suitable condition for growth, although we do not know the exact mechanism." He suggests that green light may activate brain functions related to appetite and behavior, increasing the feed consumption.

In this study, it was confirmed that irradiating green light can promote the growth of flatfish species, but no effect was recognized in other species such as pufferfish and salmon.

Applied to other flatfish species and shipments begin

By simply adding LED lamps indoors where normal raising of flatfish is performed, the growth of these fish can be promoted. This method is applicable not only to spotted halibut but also to other flatfish species such as marbled sole and Japanese flounder. Therefore, it can be utilized in flatfish aquaculture and seedling production nationwide in Japan.

Since 2020, the research group has been conducting experimental cultivation of spotted halibut in collaboration with several municipalities and fisheries cooperatives in Iwate Prefecture and other areas, and they have shipped adult fish to the market for three consecutive years. These research results attracted the interest of several flounder farmers in Oita Prefecture, and they began to utilize the technology in order to shorten the raising period and advance the shipping timing of Japanese flounder.

Glossary

*Aquaculture : In this article, "aquaculture" involves not only raising fry in enclosures such as fish net pens or tanks, until they reach a size suitable to be shipped out for consumption, but also human intervention during the most vulnerable period from egg to fry, after which period the fry are released into the natural sea.

Project name

The special scheme project on regional developing strategy

Project period

From May 2016 to March 2018

Title

Establishment of a Low-Cost Production System for the Aquaculture of Regionally Important Fish Species

Leading research institutes

National Association for the Promotion of Productive Seas (representative institution), the Japan Fisheries Research and Education Agency, The Kitasato Institute (Kitasato University), Stanley Electric Co., Ltd., Miyagi Prefecture Fisheries Technology Institute, Fukushima Prefectural Research Institute of Fisheries Resources, Kanagawa Prefectural Fisheries Technology Center, KANAGAWA Sea-Farming Association