(This is an English translation of the original Japanese article.

The publication date refers to that of the Japanese version,

which differs from the upload date of the English version.)

A research group represented by Kokusai Kogyo Co., Ltd. has developed a method to inspect the aging of agricultural water facilities using drones, and compiled and released a manual based on it. Since drones can easily approach facilities located on steep slopes or those without access roads and difficult for people to enter, they are expected to improve the efficiency and reduce the labor required for inspection work.

Deteriorating agricultural water facilities

One of the challenges facing Japanese agriculture is the aging of water facilities such as dams and irrigation canals. Many of the existing approx. 7,000 agricultural water facilities (key dams, headworks (see Photo 1 and Glossary 1), pumping stations, etc.) were built during the post-war period of increased food production and high economic growth, and about 20% of them have already exceeded their service life and are aging. As facilities deteriorate beyond a certain point, large-scale countermeasures become necessary. Therefore, it is important to monitor the degree of deterioration to determine the need for early intervention and to implement countermeasures in a planned manner. However, the number of workers and technicians responsible for maintaining and managing agricultural water facilities is decreasing. Additionally, dams and embankments are often located in steep or inaccessible areas without connecting roads, making manual inspection difficult. This raises concerns about sudden accidents and a decline in facility functions due to aging.

Photo 1: Head work (provided by Kokusai Kogyo Co., Ltd.)

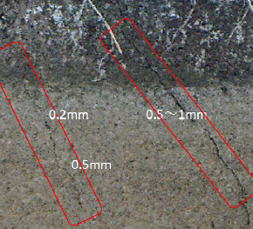

Even 0.2mm crack can be recognized

Although it depends on the structure, conditions, etc., it is necessary to observe deformations with crack widths of 0.2mm or more to evaluate the soundness of agricultural water facilities.

The drone developed by the research group uses GNSS (Global Navigation Satellite System) to determine its flight path and autonomously follows a pre-programmed course, allowing it to access locations that are difficult for people to reach.Furthermore, aerial photography and inspection methods using drones are highly accurate, capable of capturing cracks as narrow as 0.2mm (Photo 2).

While traditional methods relied on human visual inspection, drone-based inspection has reduced labor by about 20%.

Photo 2: 0.2 mm cracks can be photographed

(provided by Kokusai Kogyo Co., Ltd.)

Building a technical system to evaluate facility soundness and predict deterioration

The research group also used remote 3D measurement of water facilities (see Glossary 2) to extract and measure external changes such as subsidence and cracks. They incorporated advanced AI (machine learning) technology to evaluate the status of agricultural water facilities and predict their deterioration. By using AI to objectively evaluate infrastructure, the traditional method of relying on skilled technicians to conduct comprehensive evaluations based on facility-wide surveys can be automated. This allows for an objective prediction of remaining life and quick decision on whether repair work is necessary.

Releasing survey method manual

This survey method can be used not only for agricultural water facilities such as dams, headworks, drainage pumping stations, and open channels, but also for coastal conservation facilities such as reclamation embankments for farmland preservation. The research group has organized a case study of aging judgment tests at a total of 16 facilities and published a following manual to help field technicians conduct specific and efficient inspections: "Guide to UAV Measurement Inspection Methods (Draft) - Coastal Conservation and Agricultural Water Facilities - March 2021."

(URL:https://www.naro.go.jp/publicity_report/press/laboratory/nire/143561.html)

Creating a new system in the field of civil engineering and construction

One factor contributing to low productivity in the construction industry is the use of 2D paper drawings to carry out various tasks. Experience is required to imagine the finished shape from 2D drawings. In the manufacturing industry, including the automotive industry, productivity is enhanced through the use of 3D electronic data (3D models). Similarly, in the construction industry, productivity can be improved by utilizing 3D models, and if information such as components is linked to the 3D model, not only productivity but also quality can be improved. In the construction field, this process of linking various information to 3D models and utilizing them is called BIM/CIM (Building/Construction Information Modeling). With the progress of business reform using IT technology (DX: Digital Transformation), new technologies are being developed and introduced to digitize and automate construction processes, and various efforts are being made in Japan.

Mr. Nishioka of Kokusai Kogyo Co., Ltd., the representative institution of the research group, said, "In the future, the acquisition of 3D point cloud data (see Glossary 3) for maintenance and management of existing facilities and for surveying and designing new facilities will expand in the civil engineering and construction field. The need for distribution and utilization of 3D data will increase. Therefore, we aim to contribute to the creation of a new system which will allow stakeholders in the upstream and downstream infrastructure business to share and distribute digital information, including 3D point cloud data. This will enable work at each stage to be carried out smoothly and efficiently."

Glossary 1

Headwork: A facility, such as a sluice gate or weir, that dams a river to raise the water level and divert it into an irrigation canal. It is called as such because it is located at the head of the canal. When photographing the concrete walls of a headwork, it is necessary to observe any cracks wider than 0.2mm, as per outlined in the Guidelines for Maintaining the Functionality of Agricultural Water facilities: Headwork (Rural Development Bureau, Ministry of Agriculture, Forestry and Fisheries, August 2016).

Glossary 2

3D measurement: A process of obtaining the 3D coordinates of an object along the XYZ axes, and measuring its dimensions, position, and contours to acquire 3D information.

Glossary 3

Point cloud data: A collection of points with 3D coordinates obtained through 3D measurement using drones or other methods. It is also sometimes called a "point cloud."

Project name

R&D Matching Funds on the Field for Knowledge Integration and Innovation

Project period

FY2016 to 2019

Title

Technology Development for Advanced Stock Management of Agricultural Water Facilities

Leading research institutes

Kokusai Kogyo Co., Ltd., Institute for Rural Engineering of National Agriculture and Food Research Organization, Applied Technology Co., Ltd., Aquatic Zone Network Co., Ltd., Fujifilm Corporation