Aiming at the establishment of the labor-saving cultivation system, the National Agriculture and Food Research Organization (NARO), in collaboration with Ritsumeikan University and an auto parts manufacturer DENSO Corp., has developed a prototype of a harvesting robot that can pick a fruit at the same speed as a person. The video of the harvesting robot picking fruits is open to the public. We will continue the demonstration projects and aim to introduce the product to orchards around the country.

Overview

Today, we announce the development of a prototype of an automated fruit harvesting robot for apples, Japanese pears, and Western pears in V-shaped trees.

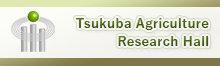

The project team has been developing optimal tree shapes and planting techniques for automated operations in fruit trees of nine kinds as citrus and apples: For example, dense planting techniques of V-shaped trees and trees of other forms. The team also has engaged in the R&D of unmanned ground vehicle (UGV) for various usages and automated harvesting robots that work well with these tree shapes.

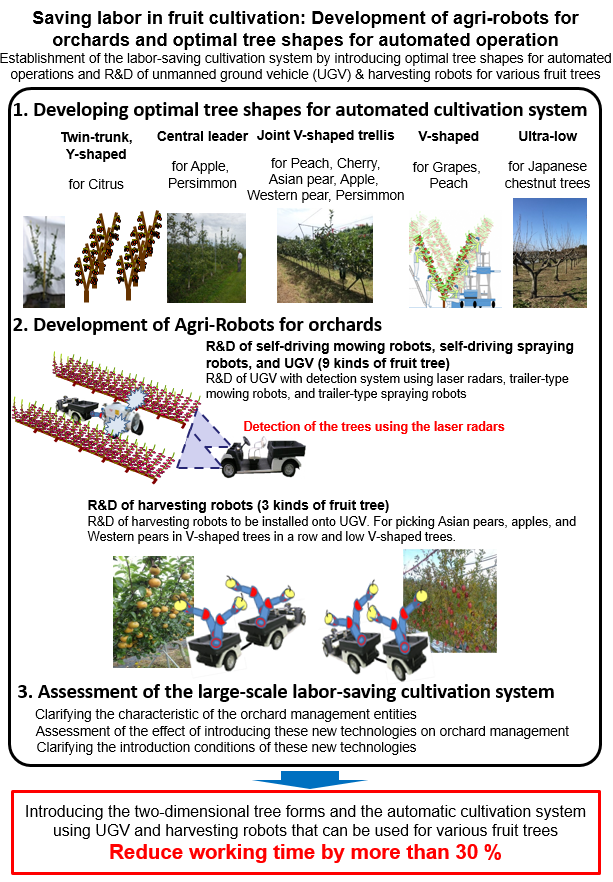

The robot prototype moves between the trees using UGV and picks fruits with two robot arms. The harvested fruits are collected into the automated fruit storage system set on UGV. When a container of the automated fruit storage system becomes full, it is replaced by an empty container while the robot continues harvesting. The prototype picks a fruit approximately at eleven seconds, which is about the same speed as a person.

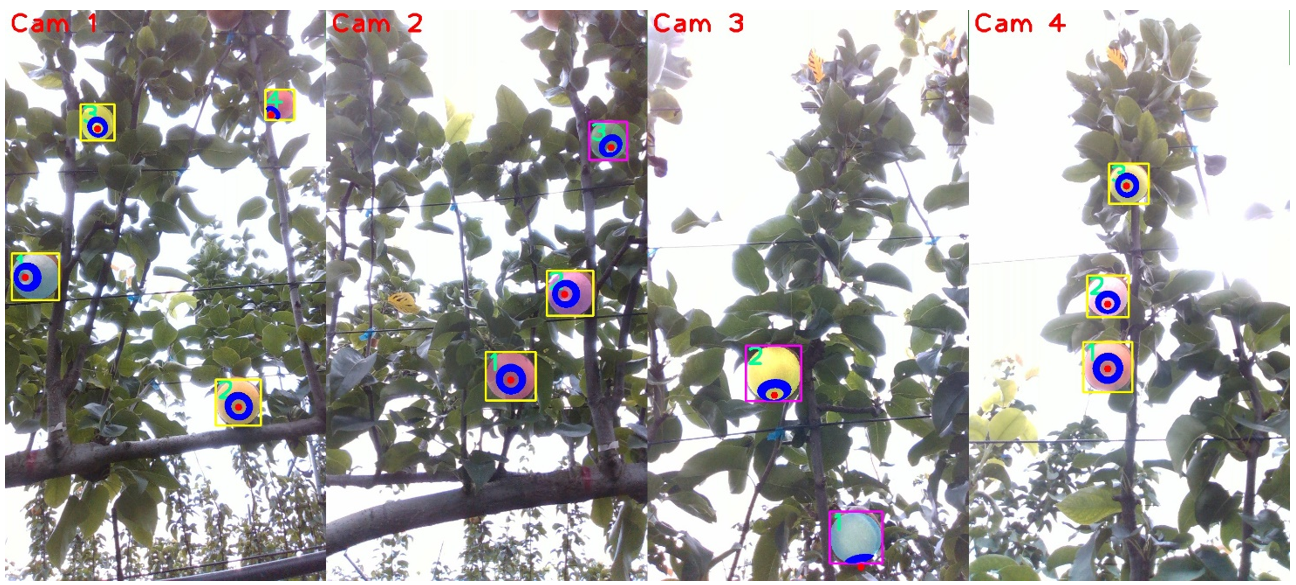

In this project, Ritsumeikan University developed software for fruit position detection using sensors and judging the ripening fruits. DENSO Corp. took advantage of its technical strength to develop the hardware of the harvesting robot.

Click here to watch the harvesting robot picking fruits.

Research Budget

This research was supported by grants from the Project of the Bio-oriented Technology Research Advancement Institution、 NARO(the research project for the future agricultural production utilizing artificial intelligence)

Publications

Yuki Onishi, et al., 2019. An automated fruit harvesting robot by using deep learning. ROBOMECH Journal. 6(13), 1-8. DOI: https://doi.org/10.1186/s40648-019-0141-2

For Inquiries

Contact: http://www.naro.affrc.go.jp/english/inquiry/index.html

Reference Information

Fig.1 Overview of the project

Fig.2 The harvesting robot developed by the project team

Fig3. Fruit position detection using deep learning (Japanese pears in joint V-shaped trellis)The fruit surrounded by a square shows the success in detection. Double circles in blue and red show where the calyx ends of the fruits are located. The detection system uses the color around the calyx end to judge whether the fruit is ripe and ready to be harvested. The four pictures (Cam 1 - Cam 4) are taken simultaneously by the four RGB-D cameras installed on the harvesting robot. The green numbers in each picture show the consecutive numbers of detection by each camera.