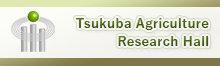

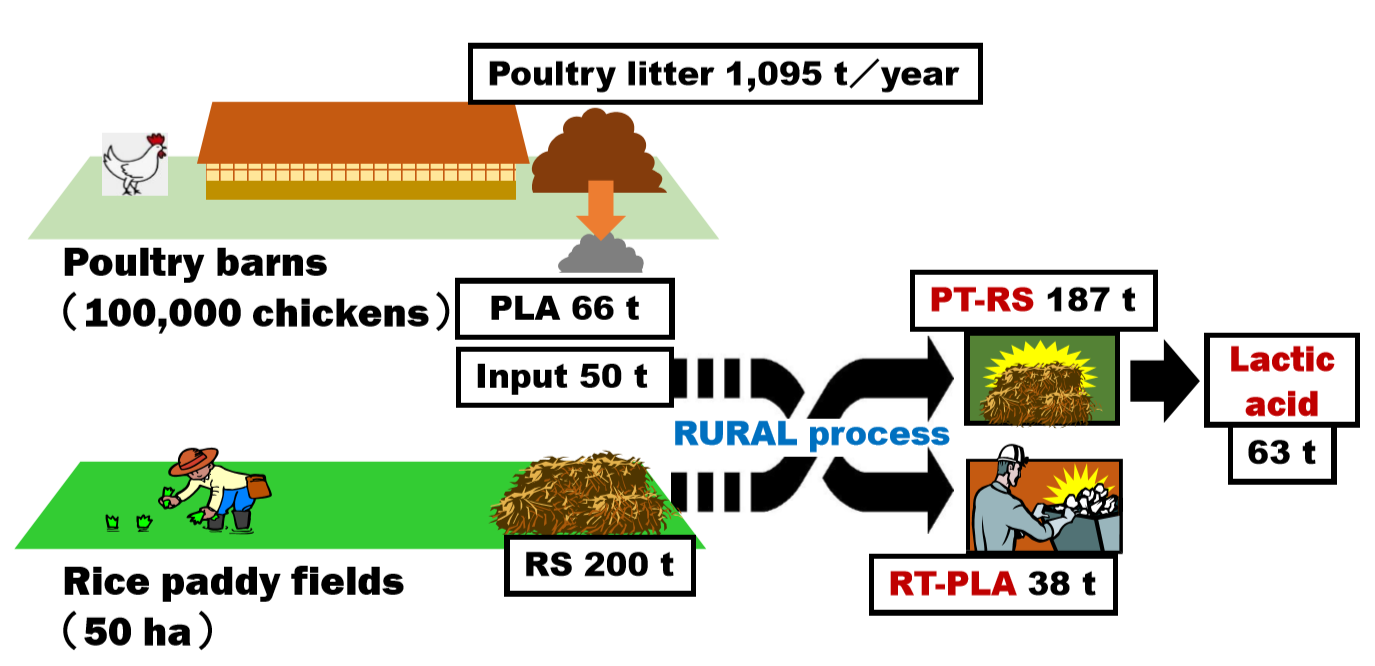

The National Agriculture and Food Research Organization (NARO) has developed a methodology for upgrading rice straw and poultry litter ash into more useful products by mixing them with water for reaction during storage. The developed method is called the "RURAL (Reciprocal Upgrading for Recycling of Ash and Lignocellulosics) process". The rice straw which goes through this process becomes susceptible to enzymatic saccharification, which makes the production of glucose, lactic acid for biodegradable plastic much easier. On the other hand, calcium in the poultry litter ash moves to the straw and water to lower the ash alkalinity, which makes the treated ash easier to use as a recycled phosphorus source for fertilizer. The RURAL process will convert the resources from the agriculture and livestock industry into two strategic primary products with added value, thus promotes the creation of the rural bioeconomy.

Overview

Food production practice in agriculture and food industries generates various waste products and by-products that can be recycled. Recently, there have been rising social expectations to increase the social and economic value of these reusable biological resources, foster its utilization, and contribute to a sustainable society.

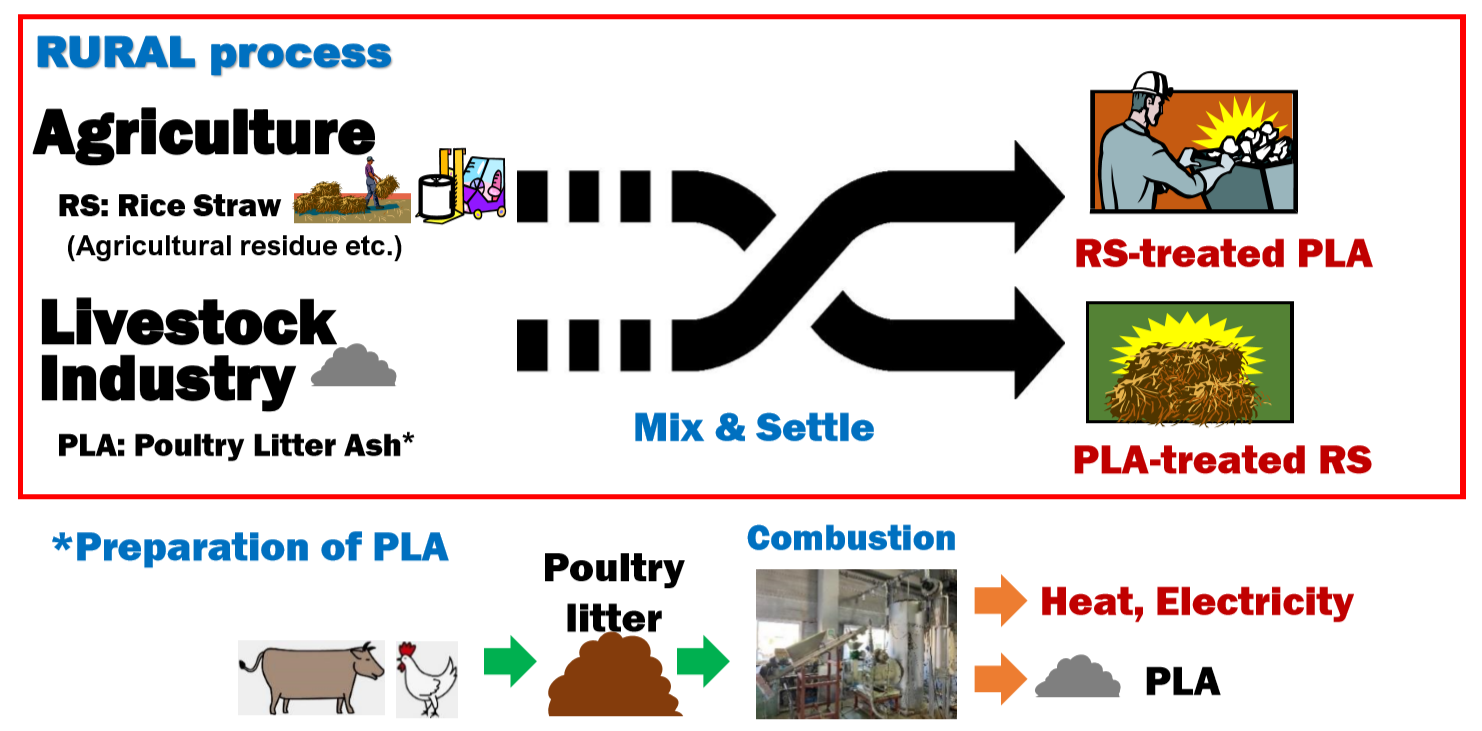

In this study, NARO engaged in the attempt to upgrade the utility value of rice straw (RS), an agricultural residue from rice production, etc., and poultry litter ash (PLA). The conventional process to produce biofuel and chemical materials from plant residues includes acid, alkali, or steam explosion pretreatments which is expensive and requires large-scale facilities. The PLA gained after the combustion of poultry litter to generate heat and electricity is a phosphorus source for producing fertilizer but is not easy to handle because of its high alkaline quality. The RURAL process realizes the simultaneous modification of two resources: RS and PLA, through wet storage.

The new process allows individual farmers to perform a small-scale RS pretreatment without the need for a large facility by storing the pile of mixed ingredients with covering in their farm site. Moreover, there is no need to transport fossil-origin alkali from the outside region when there is plenty of alkali from locally supplied PLA. The RS treated PLA with lower alkali becomes easier to recycle as phosphorus fertilizer. The process is simple, and its efficiency will not be affected by the size of the resource. Regions can start various research and demonstration projects for producing the strategic primary products (SPPs) according to the scale of the available resource and the local farming-livestock relationship. The RURAL process is a breakthrough in realizing the Japanese-style rural bioeconomy and is expected to contribute to strengthening the food supply system of rural areas.

Publications

Yamagishi K., Ike M., Tanaka A., Tokuyasu K., The RURAL (reciprocal upgrading for recycling of ash and lignocellulosics) process: a simple conversion of agricultural resources to strategic primary products for the rural bioeconomy, Bioresour. Technol. Rep. doi.org/10.1016/j.biteb.2020.100574 (2020).

For Inquiries

Contact: http://www.naro.affrc.go.jp/english/inquiry/index.html

Reference Information

Fig.1 The RURAL process (image)

Fig.2 The major steps of the RURAL process using RS and PLA

Fig.3 The picture of PLA (left), and the mixture of RS and PLA after controlling moisture (right)

Fig.4 Trial calculation on SPP production from the RURAL process based on the research result

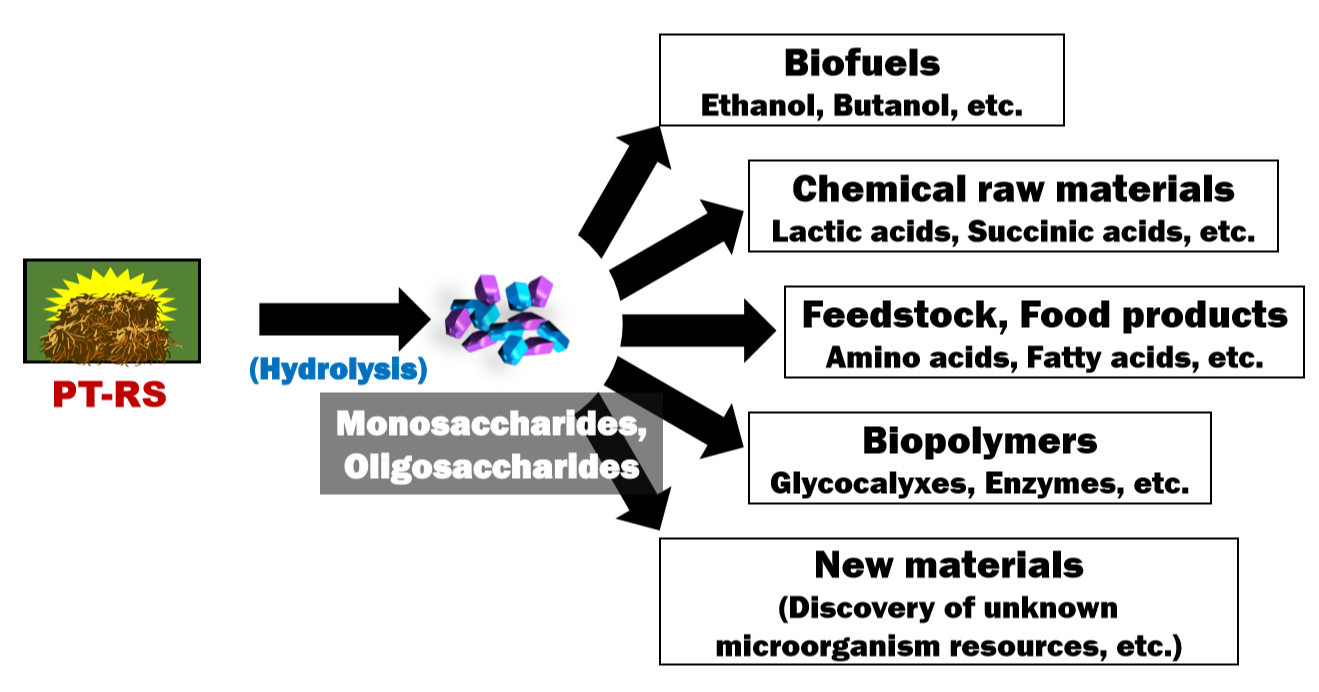

Fig.5 The possibility of versatile SPP production from sugars (image)