Many people may heard about the existence of Silkworms, but only few people have knowledge beyond "caterpillars that make cocoons from which silk is made", "eats mulberry leaves"etc. But actually, the silkworm is an amazing insect! Here, we will introduce the mysterious ecology of the silkworm and the latest Japanese Glowing silk that is gaining attention worldwide.

Silkworms are entirely dependent on humans for survival

The silkworm has been bred from wild mulberry silkmoth. Humans have tamed and domesticated it over the course of several thousand years. The varieties have been repeatedly improved with the aim of efficient production of a large amount of better-quality raw silk. Silkworm larvae barely move, and although adults have wings, they cannot fly. Silkworms cannot survive without care from human.

Various characteristics of Silkworms

Among large number of silkworm stocks, you can find various genetic characteristics, such as large cocoons that produce a lot of silk, yellow cocoons that produce thin silk, and strains that are resistant to disease. In addition to the silkworms bred by sericulture farmers, there are currently about 1,900 stocks of silkworms in Japan, including those preserved in research institutes and universities. NARO preserves about 600 of these species as genetic resources.

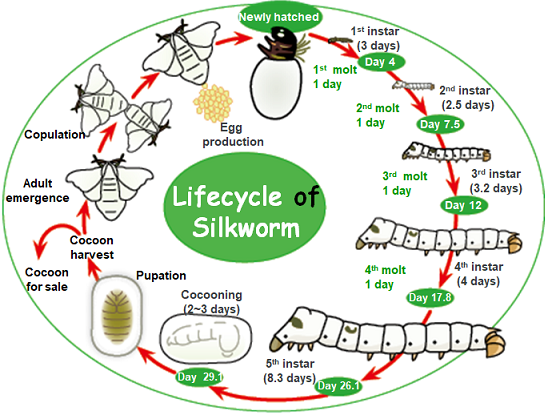

Life cycle of a Silkworm

Let's learn about the life cycle of silkworm and cocoon production. As shown in the image (right), silkworm larvae that hatch from eggs will molt (emerging with new skin) four times. During their larval stage they are fed solely with mulberry leaves. In about 25 days they increase their weight for a remarkable 10,000 times more than the hatchlings. When silkworms reach the fifth instar, they spin silk (silk thread) and create a cocoon to wrap themselves in, inside which they become pupa. These cocoons are shipped, dried, and processed into raw silk. Silkworms for egg production are kept as cocoons without drying and adult moths emerge after about two weeks after spinning. They will mate shortly thereafter and lay around 500 eggs. Adults cannot fly and do not eat, completing their short life cycle in about a week.

Due to the decline in the numbers of the sericultural farmers, domestic raw silk occupies only 0.2% of Japanese market. Silk is known as the "queen of fibers". The luster and texture of natural silk are popular and has high demand worldwide. For the popularization of Japanese silk, NARO is conducting research to develop new varieties through crossbreeding and using genetic modification technology to create silk with new functions. Here we introduce some of them.

Ultrafine silk that can be dyed with less dye

With the most reared breeds, the thickness of the cocoon thread produced by sericulture farmers is about 3 denier, "Reimei" is a 1.5 denier ultra-fine silk developed by NARO, which is thinner than the 1.6 denier of the "Hakugin" silkworm variety, which used to be the world's thinnest. Ultra-fine silk of "Reimei" has been achieved by a further improvement of "Hakugin" using genetic modification technology. Because of its thinness, number of cocoon threads used for one raw silk has been increased. The fabric woven with this raw silk has a small unevenness on the thread surface, so it has an excellent luster and texture, adding an elegant touch to dresses and Japanese clothing.

※Denier is a unit of fiber thickness. (The thickness of a thread is 1 gram per 9,000 meters.

For example, 9,000 meters of a thread weighing 50 grams is 50 deniers.)

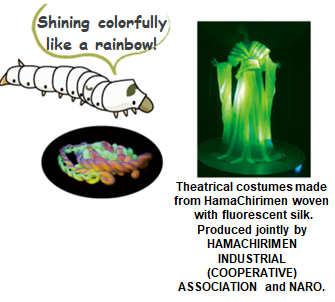

Fluorescent Silk

"Fluorescent silk" is produced by the genetically modified silkworm that express fluorescent proteins derived from jellyfish or corals in cocoon silk. The raw silk itself fluoresces in a variety of colors, including green, red and orange. Fluorescent silk has a distinct color even under natural light. When exposed to light of a certain wavelength, such as blue , and viewed through a suitable filter, the vivid fluorescent color shows up. Since it is eye-catching, it is used in the entertainment industry and in artwork.

A silkworm farm in Gunma Prefecture has become the first in the world to breed and produce green-fluorescent silkworms in 2016. By increasing production of fluorescent silk and other high-performance silk that can be found only in Japan, it is expected that the silk will be used in a wide range of fields, including clothing, art, and interior materials.

Practical production of transgenic silkworms has begun!

As of 2023, there are only 146 sericulture farms left in Japan, and the number of silk mills has decreased from 1,871 in 1959 to just 7, which indicates that Japan's sericultural industry is shrinking. However, the start of farming genetically modified silkworms and the practical production of fluorescent silk are encouraging news.

Major breakthrough in fluorescent silk commercialization

Why has the rearing of silkworms that produce fluorescent silk become news? Generally there are clear rules for handling genetically modified organisms. Breeding on a sericulture farm has been approved after investigating that there is no impact on biodiversity. NARO, in colloboration with the Gunma Prefecture Silk Technology Center, has taken a big step towards mass production of raw silk from genetically modified silkworms raised in farms, and for the commercialization of fluorescent silk products.

Ultra-fine silk in a wide range of colors

Currently, farmers can rear three varieties of genetically modified silkworms, including green-fluorescent silk, blue-fluorescent silk,and "Reimei". Furthermore, according to the current regulatory protocol sericulture farmers are allowed for raising silkworms only from the third instar and onwards.From the egg to the third instar they have to be kept in the designated facilities However, efforts are being made to expand the breeding of silkworms at silkworm farms, such as conducting tests that will enable them to raise silkworms from eggs in the future. As we move towards mass production of a wide variety of silk, each with its own unique characteristics, hopes are high for the revival of the sericulture industry and the birth of a new silk culture.

NARO is the first in the world to successfully genetically modify silkworm in 2000, and since then has been pursuing research and development in a variety of fields in addition to the traditional silk industry. It is expected that new industrial uses for the silkworm, including those already in practical use, will be developed, such as for pharmaceutical and medical materials and electronic components.

Please check the NARO website for more information about silk research

Related Video

Sericulture revolution promoted by genetic modification technology