In the first part of "Secrets of Silkworms" we introduced the mysterious ecology of silkworm and the latest silk, such as the ultra-fine silk and fluorescent silk produced by genetically modified silkworms. Meanwhile, NARO has discovered new, previously unimagined value in silkworm silk, and conducting research to develop new materials that utilize its properties. In this edition, we will focus on new materials made from silk, which are expected to be used in new industries such as the medical field, medical hygiene materials, cosmetics etc.

Establishment of world's first silkworm genetic engineering technology

Silkworm cocoons are composed of nearly 100% protein. This led researchers to consider that by incorporating a gene responsible for producing a specific target protein into the chromosomes of silkworms, these insects could be utilized to produce proteins suitable for use as raw materials in diagnostic drugs and pharmaceuticals. After more than a decade of research, in 2000, NARO announced that they had successfully established transgenic silkworm technology, a world-first achievement.

Utilizing the characteristics of two types of proteins to develop new materials

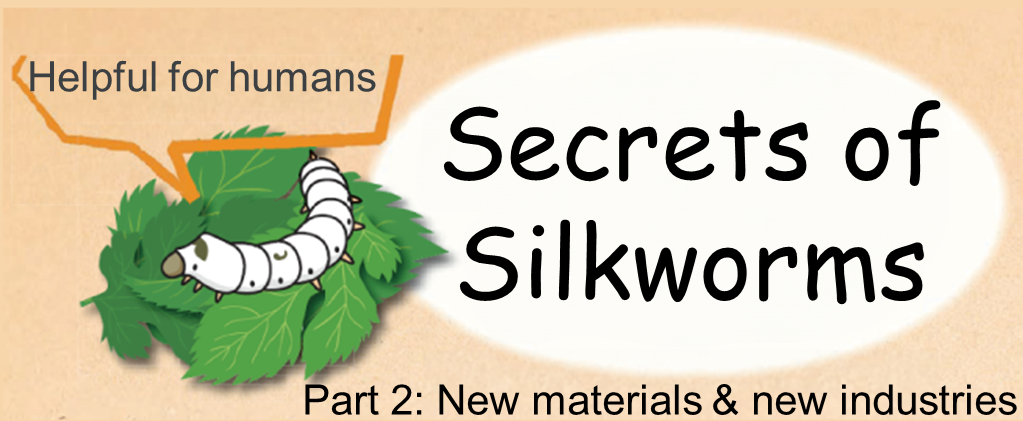

Silkworms produce cocoon threads in a specialized organs called silk glands as shown in Fig (right). The silk threads are made up of two highly pure proteins: two fibroin layers that form silk threads, and a sericin layer, which acts as a glue to connect them. When recombinant proteins are produced in the sericin layer, which is easily soluble in water, it will be possible to extract and purify the target protein with fewer impurities. At the same time, we are developing innovative silk materials by binding various proteins to those in the fibroin layer.

<Medical Field>

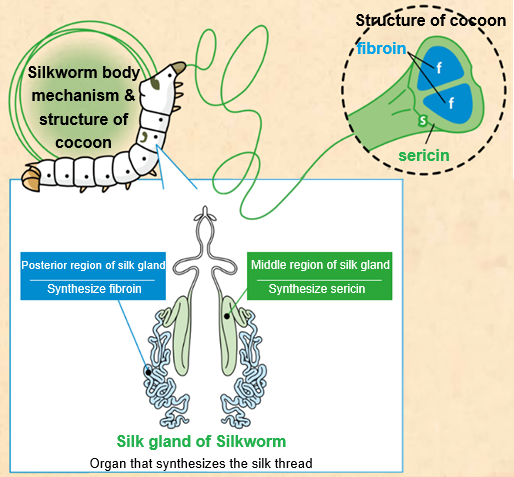

Testing and Research kits

Proteins made by genetically modified silkworms has been utilized for the development of test kits for grasping and diagnosing diseases & health conditions in humans and animals, and research kits for use in medical research, etc. Until now, the main raw protein ingredients were made from biological samples such as human blood and mouse ascites, which posed challenges in terms of stable procurement. However, using silkworms has made it possible to stably produce recombinant proteins, leading to commercialization.

Promising material for medical use

Silk fibroin has been used as a material for surgical sutures since ancient times. Currently, medical materials using silk are being developed because it is expected to have healing effects on various organs and can be easily processed into various material formats such as hydrogels, films, sponges, and nonwoven fabrics.

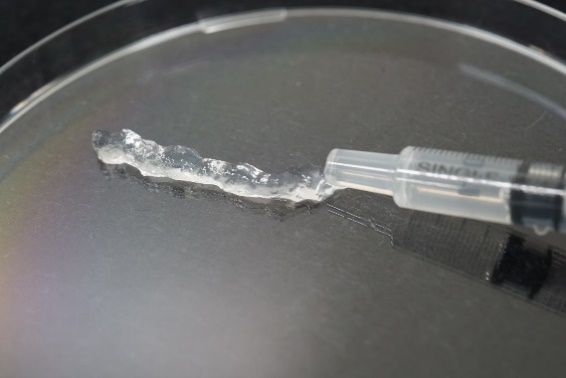

A phenomenon known as "post-operative adhesion," in which organs or tissues that are supposed to be separated become stuck together, can occur after surgery. There is a medical device called "absorbable adhesion barrier", however there is no device suitable for orthopedic surgery (especially tendons) in Japan. NARO has developed a new silk hydrogel, which shows a low affinity to cells and an enhanced biodegradation. We expect that the new silk hydrogel can be used as an absorbable adhesion barrier for tendons.

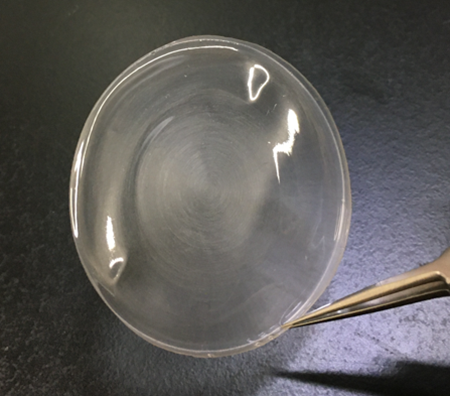

We have also developed functionalized silk fibroin modified with heparin. Heparin is one of the components of the skin tissue. We have confirmed that this functionalized silk fibroin preferentially adsorbs protein components in the blood leaking from wounds and promotes cell proliferation by enhancing cellular function; it is expected to speed up wound healing. As functionalized silk fibroin can also be processed into films, sponges, and nonwoven nanofiber sheets, it is expected to be widely used for various types and sizes of wounds.

▲A silk hydrogel that could be used as an anti-adhesion absorbable barrier (left) and a film of heparin-modified silk fibroin (right).

Affinity Silk

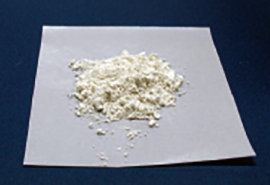

Antibodies that act against foreign substances (antigens) that have entered the body have the property (affinity) to bind to specific proteins. These characteristics of antibodies are utilized in a wide range of fields, including protein functional analysis, medical diagnostic kits, and drug development. However, since production cost of antibodies inevitably high, there was a need to establish a technology to produce them in enormous quantities and at low cost. Therefore, NARO has developed a new silk material called "affinity silk" by combining a part of an antibody with silk protein using genetically modified silkworms, which are low-cost and have excellent protein production. By processing it into aqueous solution, powder, or film, we are conducting research for its practical implementation as a material for medical diagnostic kits etc.

▲Affinity silk powder

<New industrial field>

Usage beyond the medical field! Silk material with amazing properties

Silk is expected to be used as a new material and in new industrial fields in addition to the medical fields introduced here. It can be used not only as a film, sponge, or powder, but also to create materials with different shapes and properties depending on the way of processing. Therefore, new materials and products are being introduced that further expand the possibilities of silkworms.

▶Silk, which has become popular as a material for clothing, can be transformed into a variety of forms, including not only fiber, but also powder, aqueous solution, gel, and film. Therefore, silk can be used as a raw material in wide range of fields.

Clickable Silk

Click chemistry, which won the 2022 Nobel Prize in Chemistry, is a method that can create functional molecules using a small number of simple chemical reactions and is widely used in the fields of drug development and functional material development. We have developed a production technology using genetically modified silkworms for the practical use of silk with "chemical handles" that can easily connect functional molecules. It is possible for anyone to easily create highly functional silk materials that connect various functional molecules such as pigments and drugs by applying the click chemistry method to silk. Clickable silk can be processed into fabrics, films, powders, etc. in the same way as regular silk, and mass production technology has been established for practical use. We are working toward the social implementation of silk fiber with sensing function and silk materials that combine drugs for medical purposes.

Raw materials for cosmetics

"Human collagen" has the same amino acid sequence as collagen produced in the human body. We have succeeded in producing this human collagen in the cocoon thread of genetically modified silkworms. Currently, cosmetics containing human collagen extracted from the cocoons are being produced and sold.

Raw material for electronic appliances

By treating fibroin powder with high temperature and pressure by sintering process, we have succeeded in creating a material that is difficult to conduct electricity. The use of this material in electronic components such as printed circuit boards, which are essential for computers and electronic appliances, is being considered. Also, with the rapid advancement of home appliances and IT devices, the replacement period for these devices is becoming shorter. Hence, electronic components made from silk protein are grabbing attention as a natural, environmentally friendly, renewable material

▶Use of sintered silk for printed circuit boards is being considered. (Photo is for illustrative purposes only)

<Silk production by various organism species that enriches human life>

We are not only exploring new possibilities for silkworms, but also focusing on the various species that produce silk. Applications of silk fibers in other industries as well as textiles, such as strong spider silk, bagworm silk, wild silkworms other than silkworms that produce silk thread, and hornet silk produced by hornet larvae are also expected.