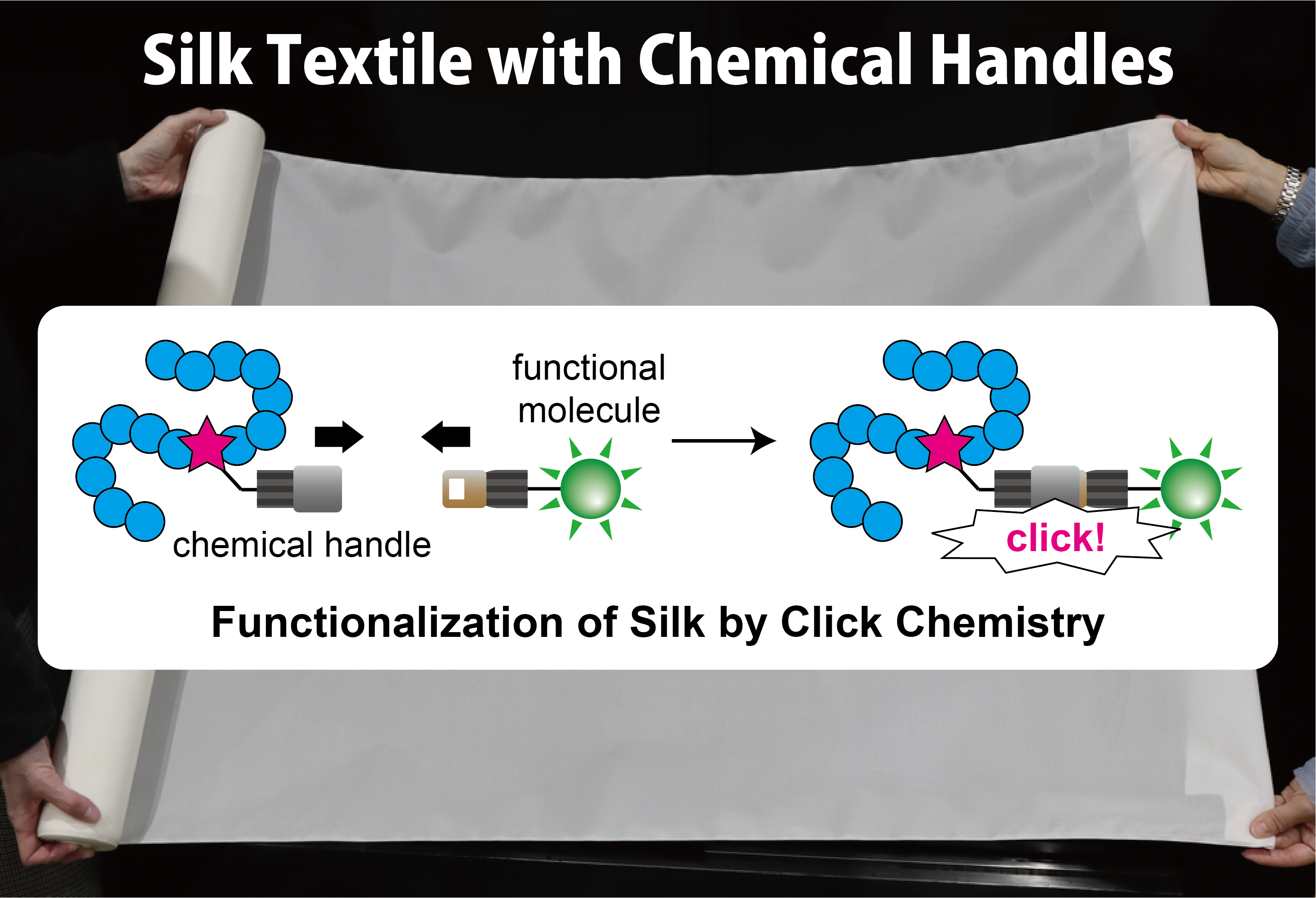

National Agriculture and Food Research Organization (NARO) has developed a production technology for the practical use of silk that incorporates "chemical handles" which can easily connect desired functional molecules by click chemistry using genetically modified silkworms. "Chemical handle" is a synthetic amino acid with a functional group called an azido group, and by connecting functional molecules such as pigments and drugs, it is possible to modify the silk properties. In 2014, we developed the basic technology, and significantly improved the efficiency of incorporating the "chemical handles"in 2018. By this research, it is expected that efforts toward the social implementation of silk fiber with sensing function and silk materials that combine drugs for medical purposes will be accelerated.

Overview

NARO is working on the research and development of silk materials with new functions with the aim of expanding the usage of silk in various fields and its applications. In this research, we have developed a production technology using genetically modified silkworms for the practical use of silk with "chemical handles" that can easily connect functional molecules. The "chemical handle" refers to the functional group namely azido group, which plays a central role in click chemistry, which won the 2022 Nobel Prize in Chemistry. It is possible for anyone to easily create highly functional silk materials that connect various functional molecules such as pigments and drugs by applying the click chemistry method to silk.

In 2014, using silkworm genetic recombination technology, we developed the world's first silk incorporating a synthetic amino acid with an azido group. In 2018, we succeeded in increasing the efficiency of incorporating synthetic amino acids into silk by about 30 times, opening the way to practical production Press Release Link. However, the genetically modified silkworms were produced based on small experimental varieties, which could produce only small quantity of silk and also the quality of the silk was not suitable for the machining required for mass production.

Therefore, in this research, the strain is improved using a conventional backcrossing method. By this, the silk production per silkworm has increased about three times and it was possible to obtain thick, long and good quality silk than before the improvement. Hence, it became possible to process it into textiles using general-purpose machines. Also, functional molecule binding tests confirmed that the "chemical handles" were retained after processing.

It is expected that this research will accelerate efforts to develop silk fibers that can measure biological information such as blood sugar levels, and silk materials for medical purposes that combine drugs such as antibiotics.

This research achievement (result) will be announced at the "69th Research Presentation Meeting of the Japanese Society of Silk Science and Technology" to be held in Tsukuba City, Ibaraki Prefecture from November 24th to 25th, 2022.

Reference Information

Tian Y, Iga M, Tsuboi H, Teramoto H "A novel transgenic silkworm line for mass production of azido-incorporated silk fiber" J. Silk Sci. Tech. Jpn. (2022) 30, 75-85.

For Inquiries

Contact: https://www.naro.go.jp/english/inquiry/index.html